beowave

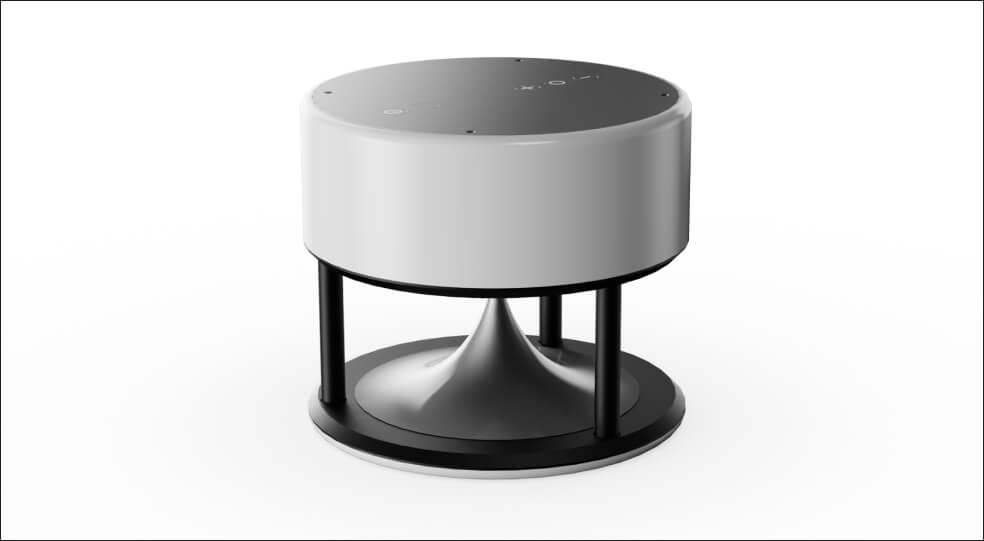

a working omnidirectional [bang & olufsen speaker] made from existing speaker parts, 20lb foam, and spray painting. <drag>

× TIMEFRAME: 14 WEEK PROJECT, 2021

× BRIEF: DESIGN A BLUETOOTH SPEAKER FROM DOSS SPEAKER PARTS USING TOOLS AVAILABLE IN THE ARTCENTER MODEL SHOP

× SKILLS: SKETCHING, FORM DEV, FABRICATION

[TABLE OF CONTENTS]

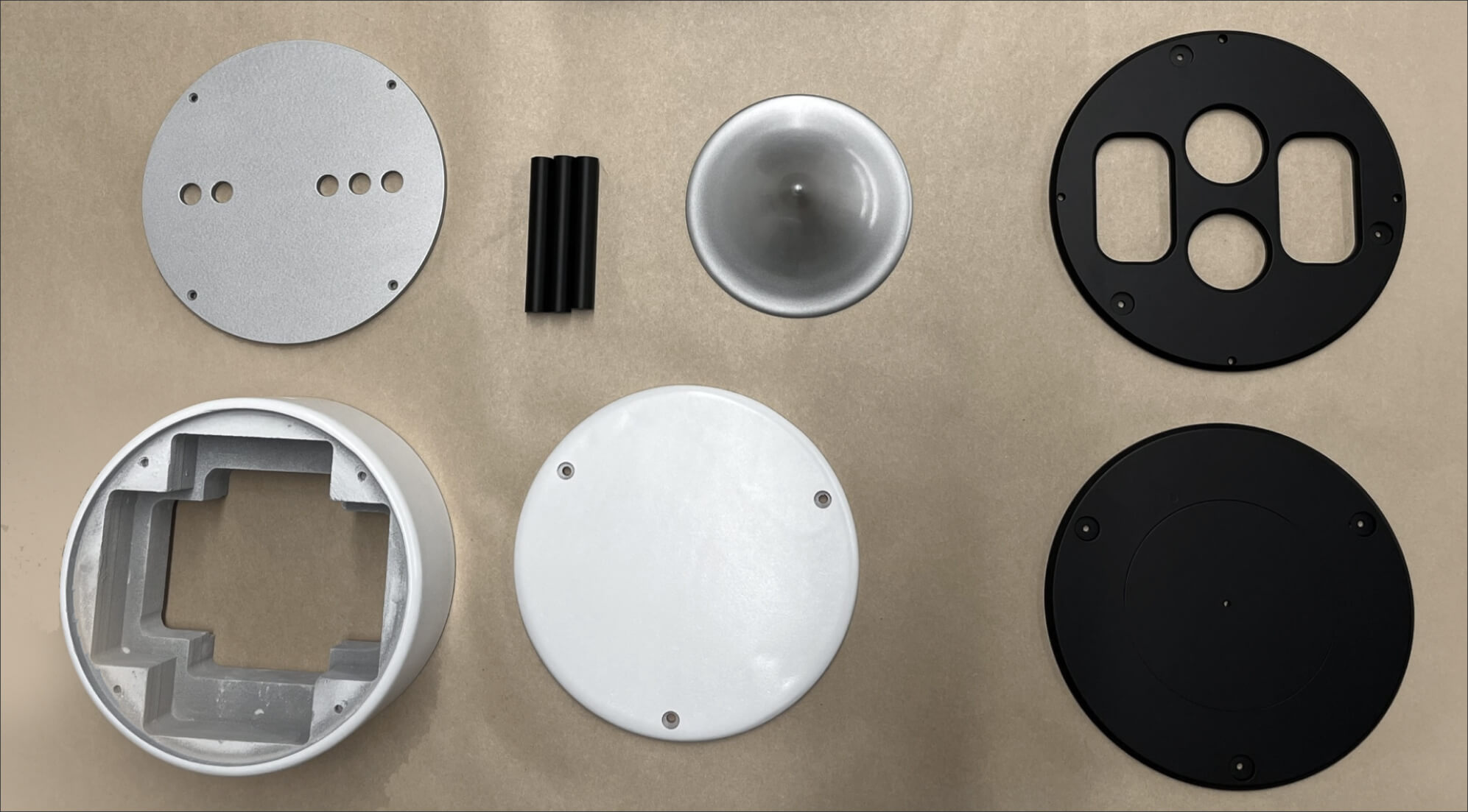

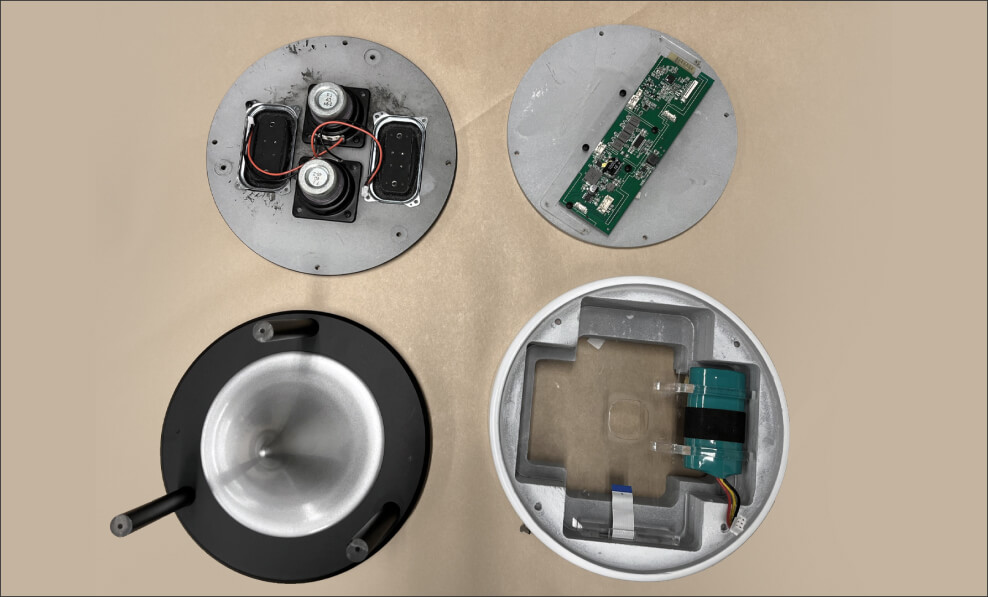

DOSS SPEAKER DISASSEMBLY

SKETCH IDEATION

01// CARDBOARD

02// MDF AND BLACK FOAM

03// 10 LB FOAM

04// FABRICATION

05// FINAL ASSEMBLY

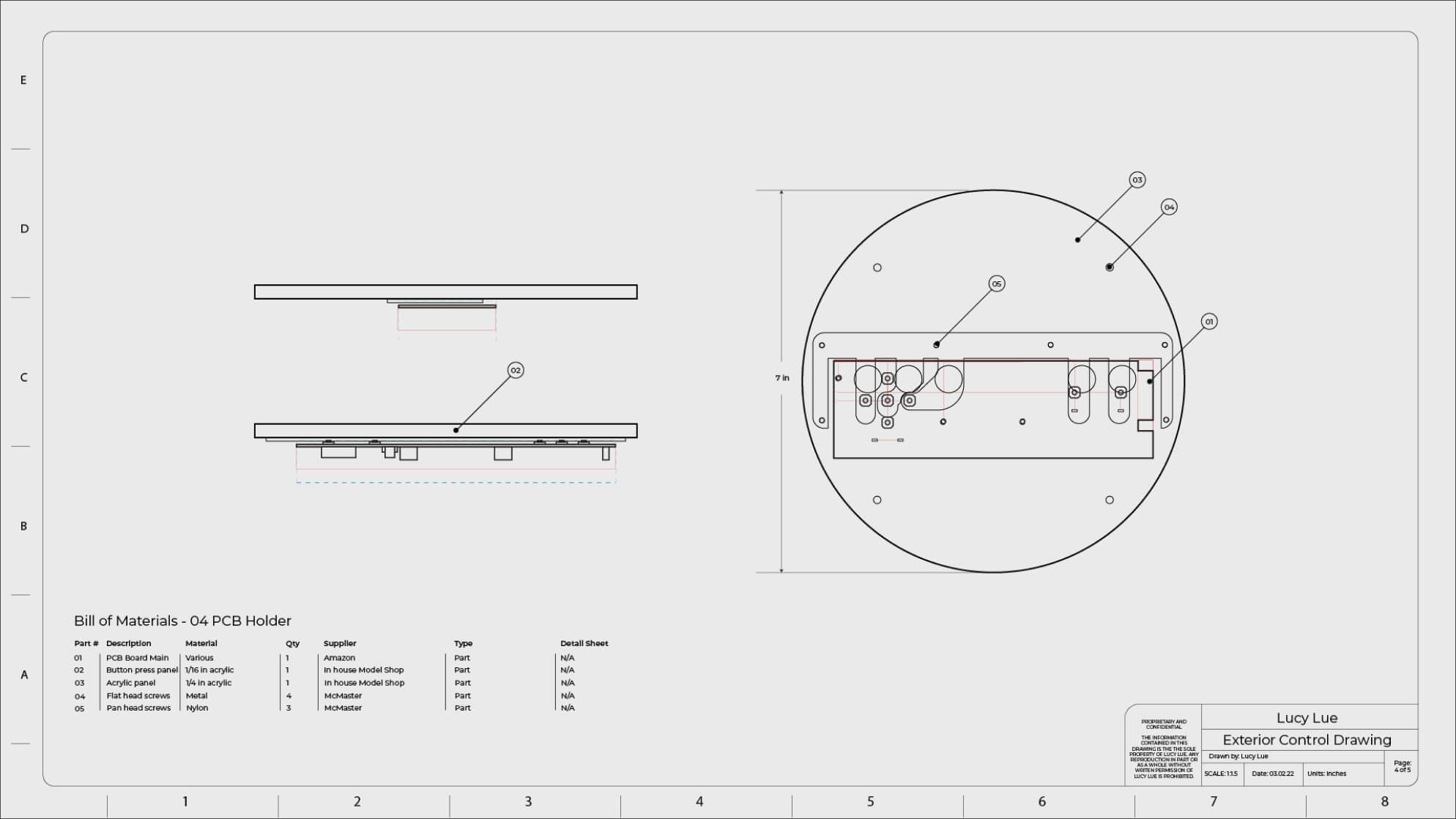

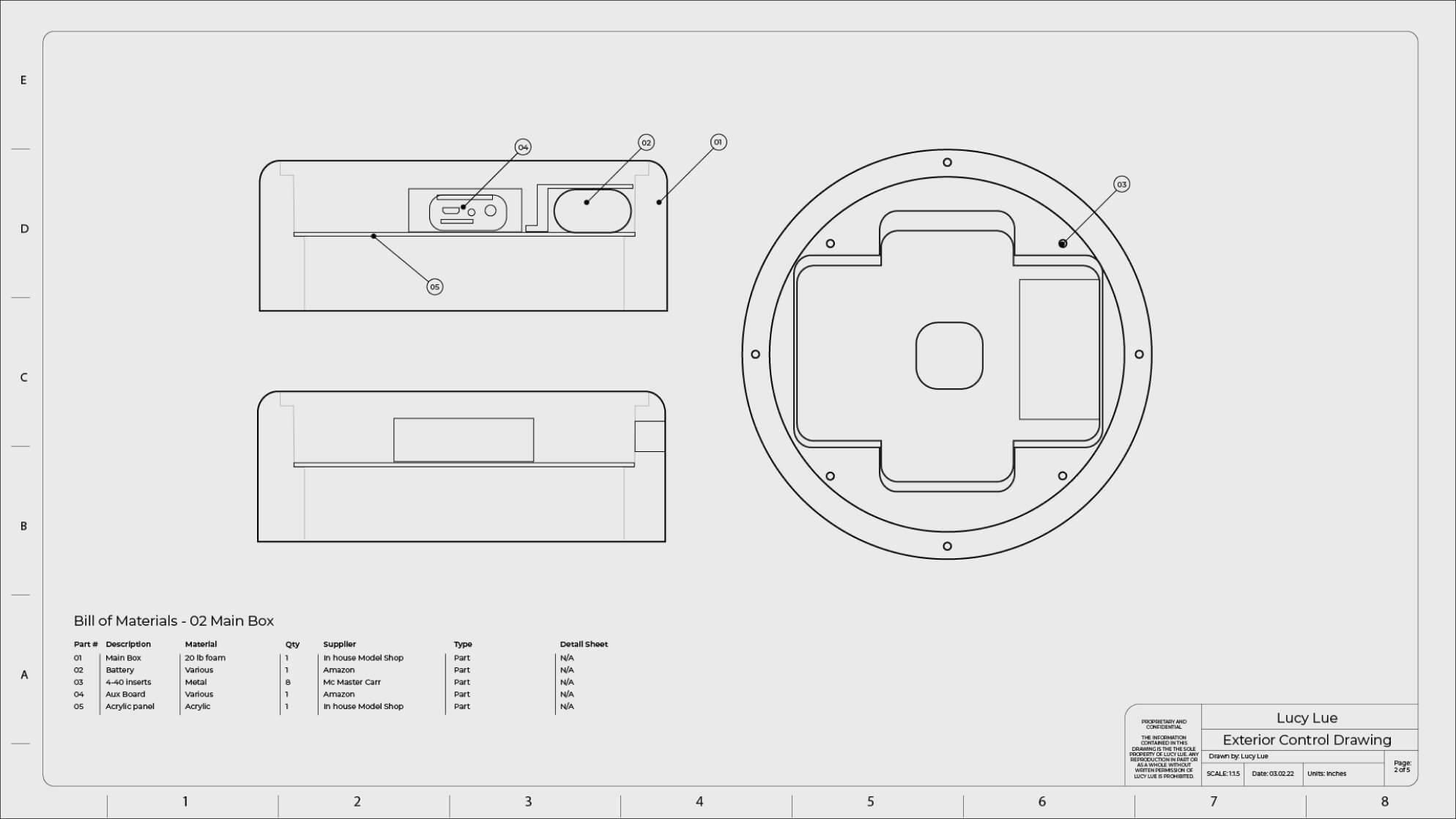

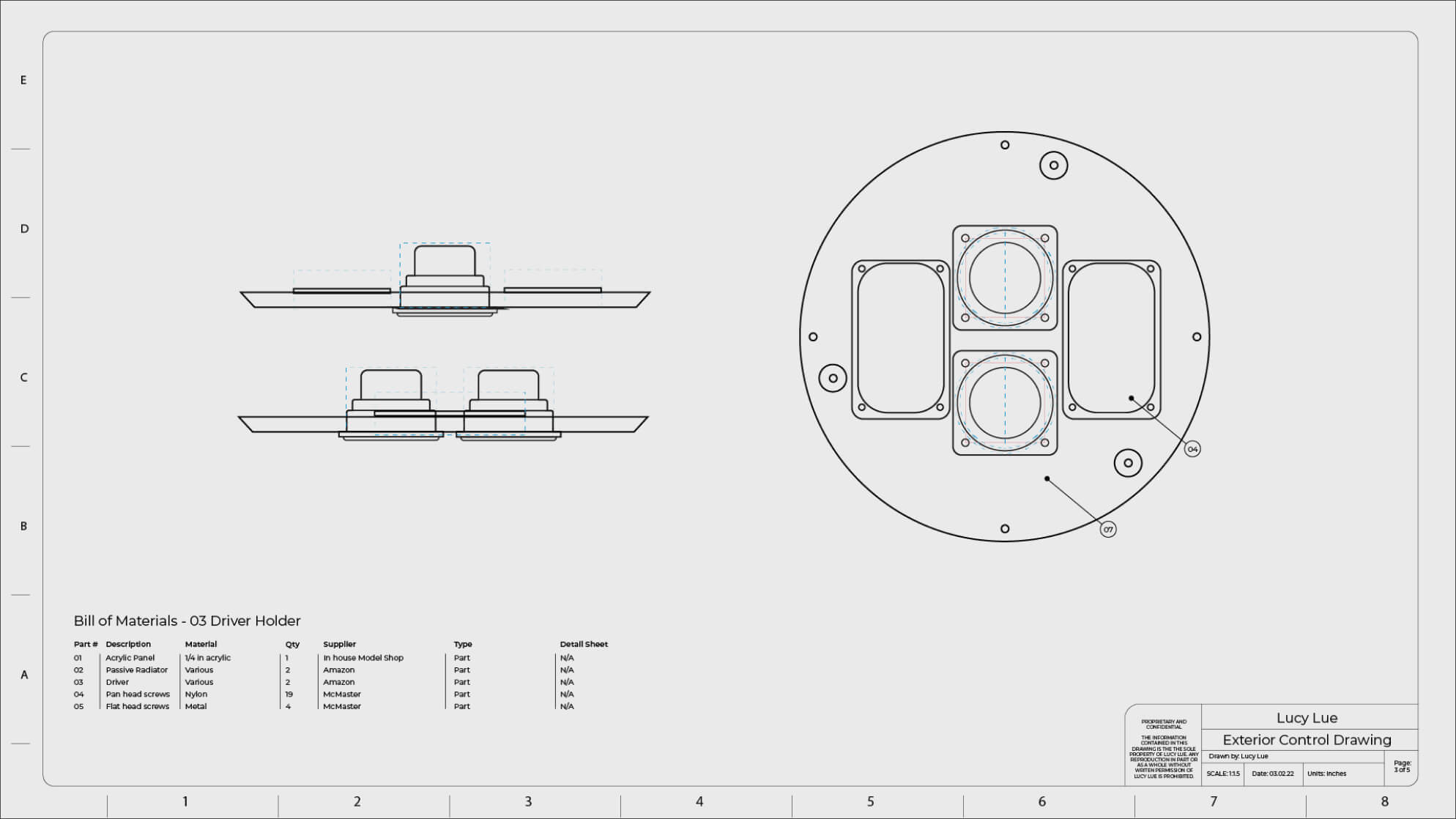

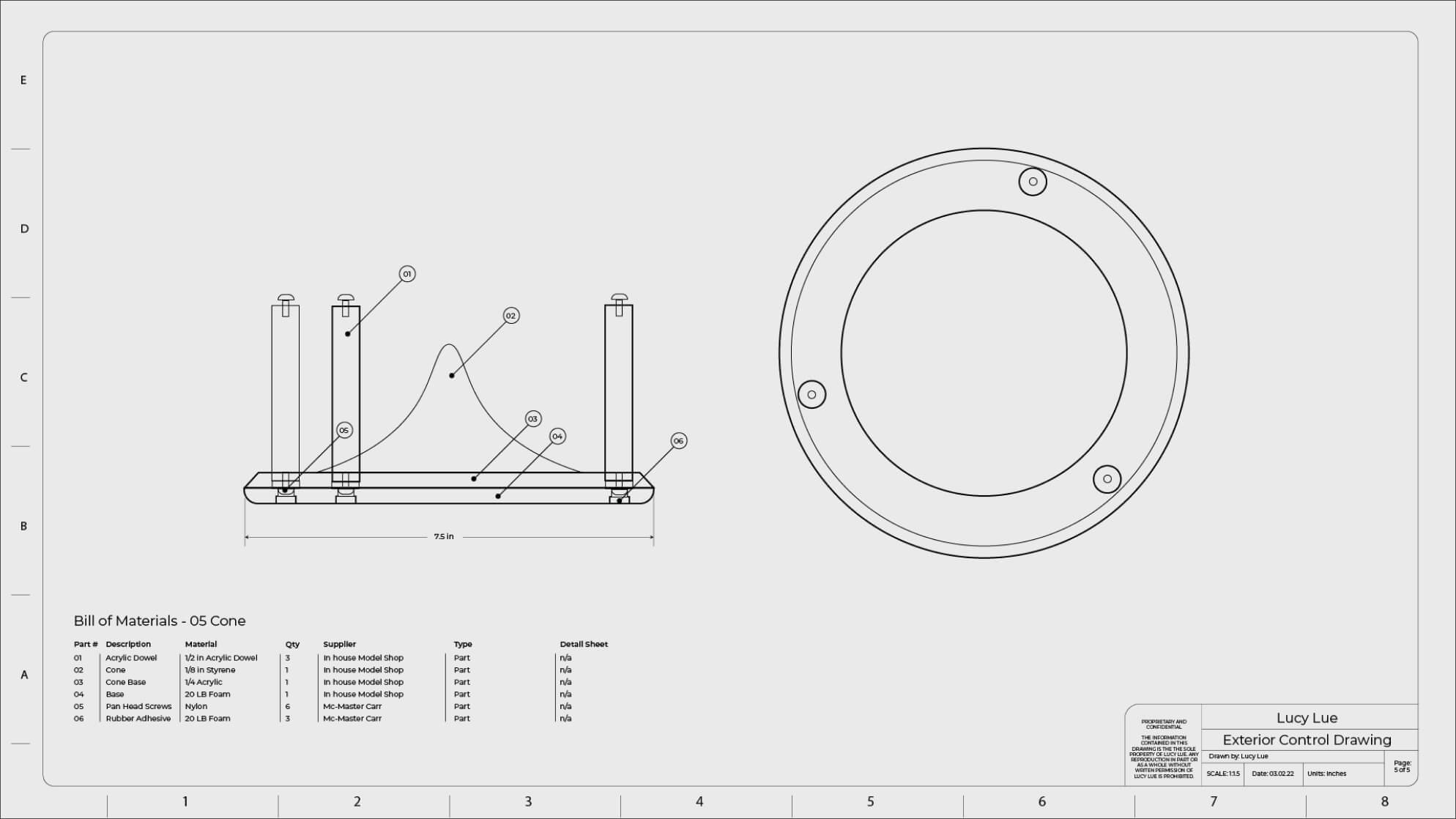

06// BLUEPRINTS

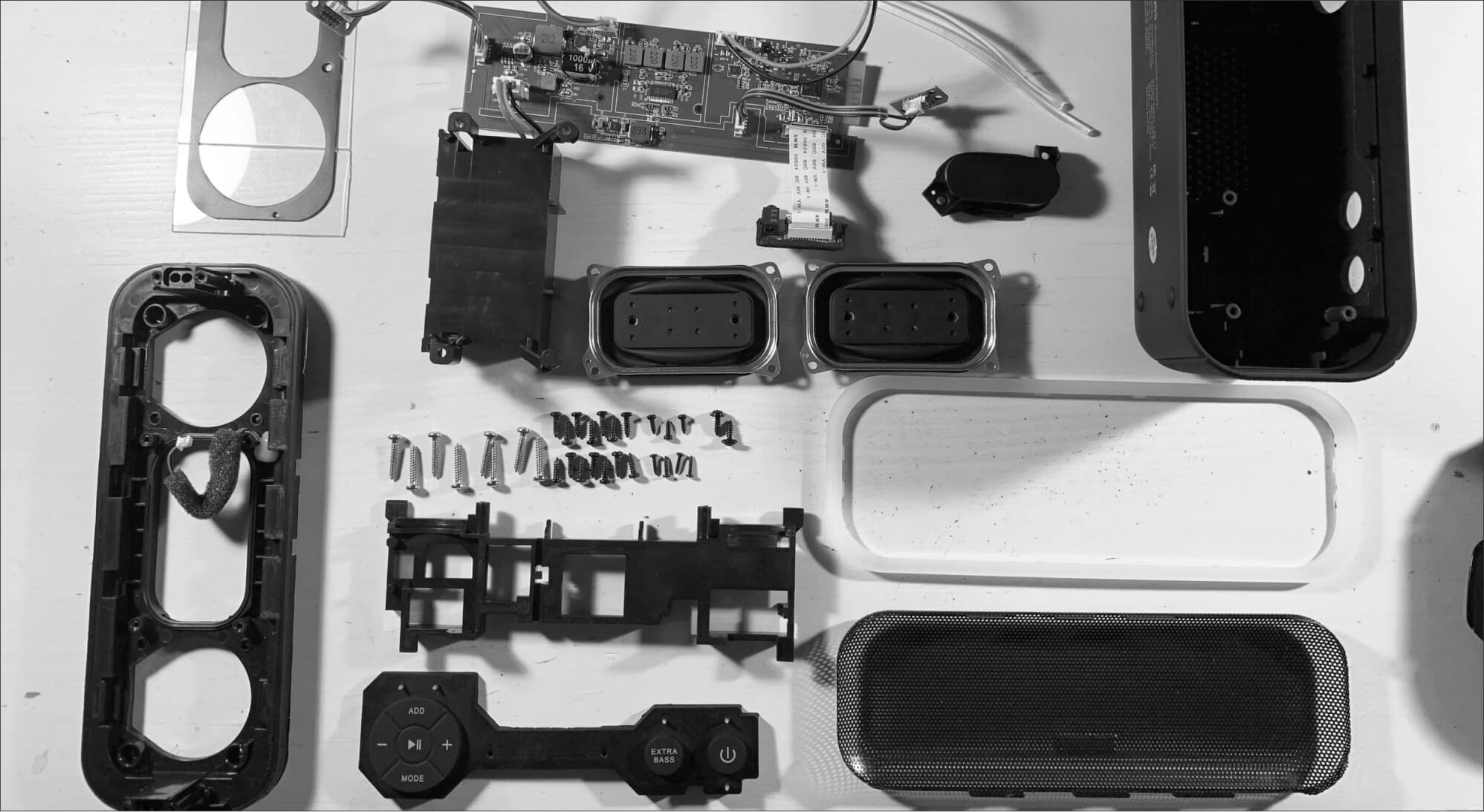

disassembling a speaker

we bought a doss speaker from amazon to disassemble. we learned about acoustics and speaker parts.

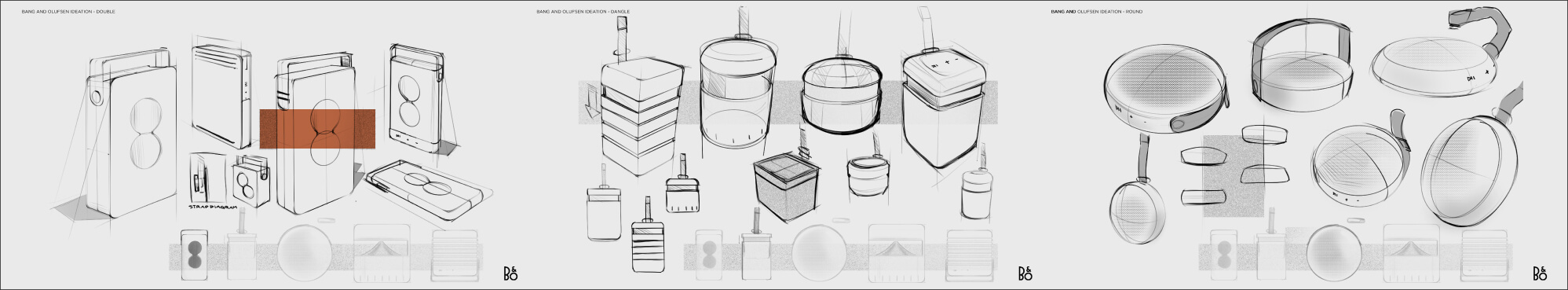

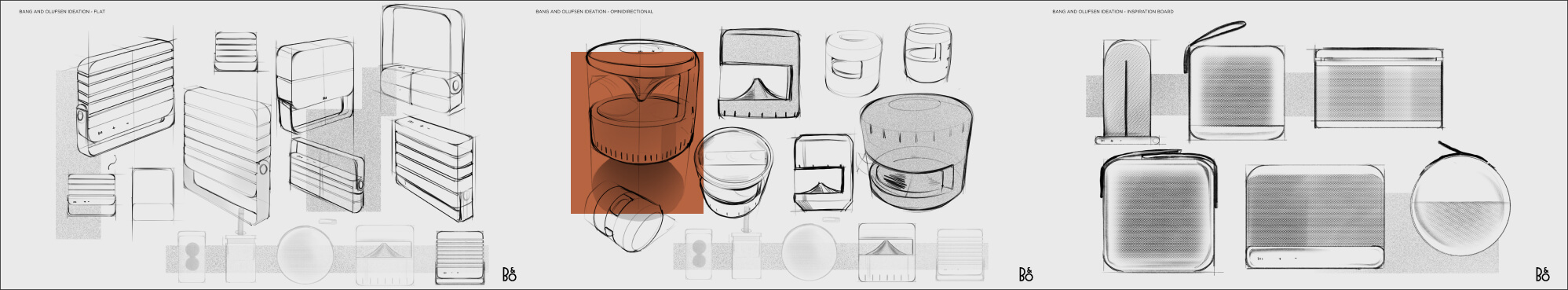

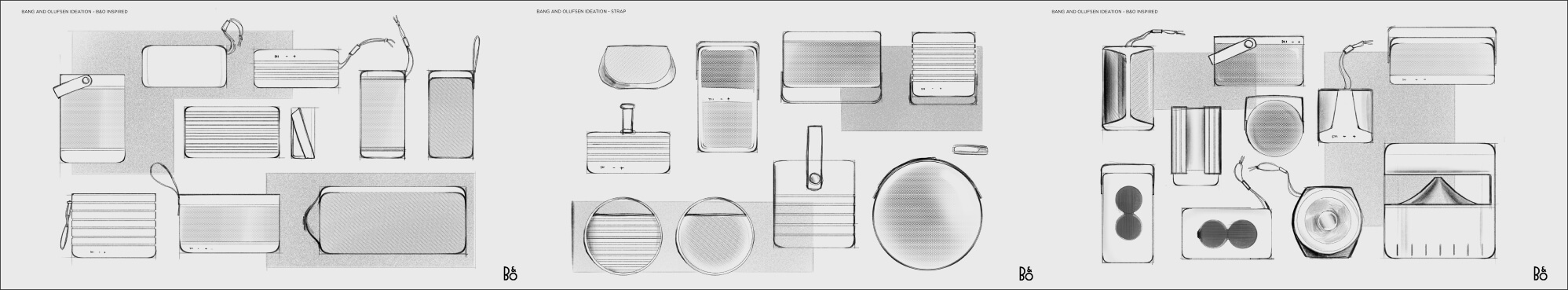

sketch ideation

i started coming up with ideas on the form with hand sketches via procreate. i chose the omnidirectional and double form since they represent B&O’s form language. <click to scroll through>

//01 cardboard

i made cardboard mockups for the 2 chosen sketches. i chose to move forward with omnidirectional since it effectively hides the speaker parts.

//02 mdf and black foam

i changed both the proportions of the speaker with the black foam and the way it was held up with the mdf to get a feel for proportions.

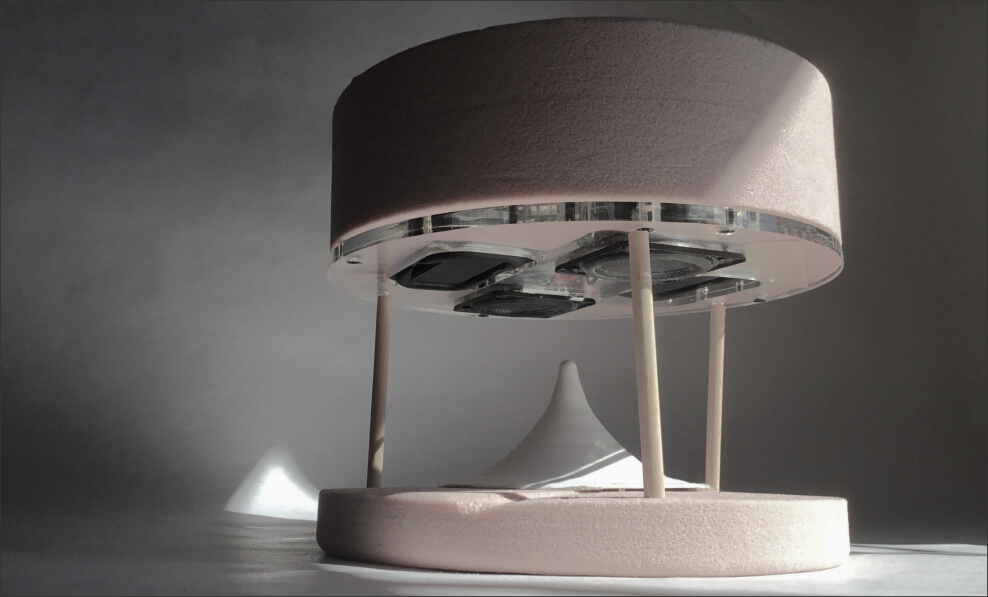

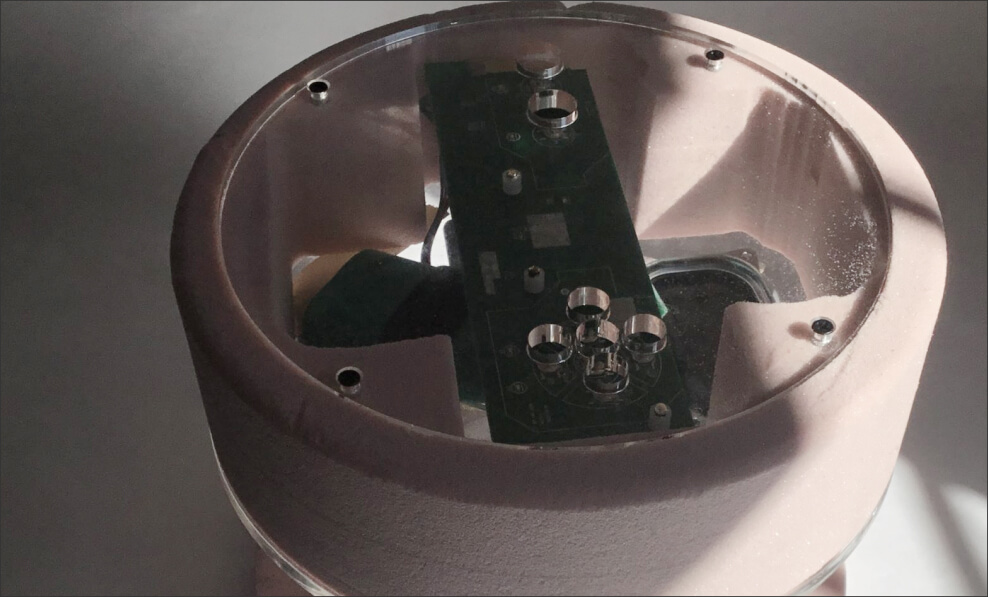

//03 10 lb foam

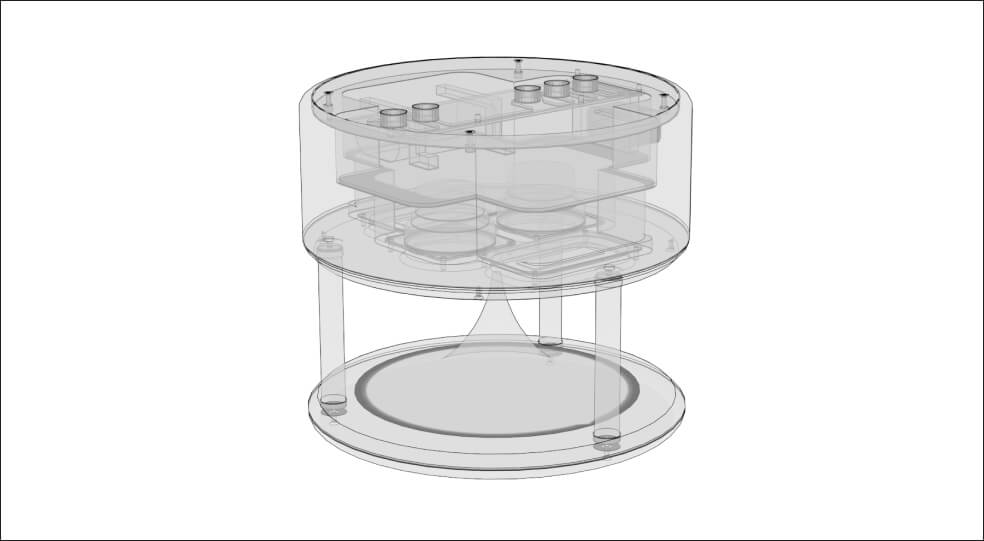

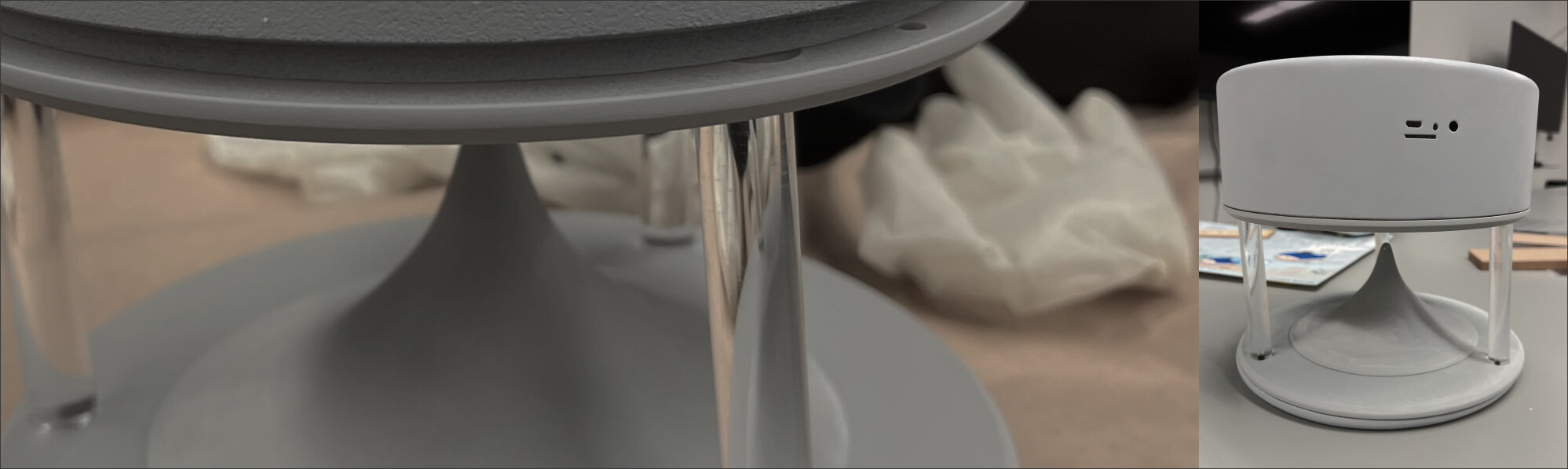

I fitted all the parts into a prototype. The thin dowels did not hold up the weight of all of the parts very well, so i had to make the dowel thicker.

//04 fabrication

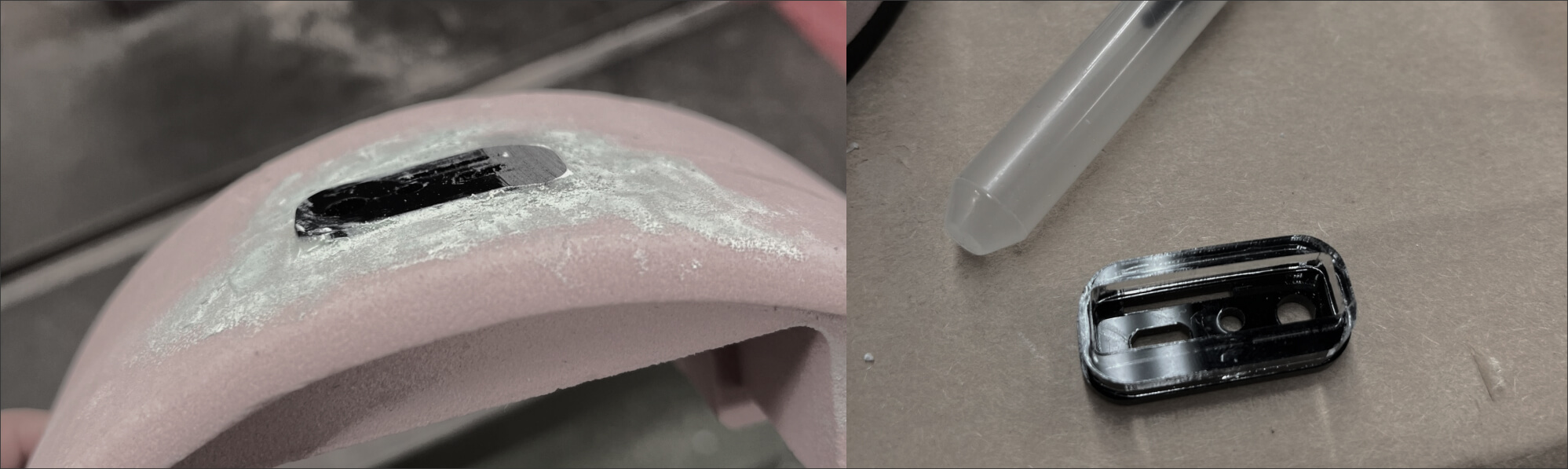

I made an acrylic encasing for the aux PCB board and used bondo to fix it onto the foam.

I sanded down the foam encasing before priming the speaker and fitting the parts.

I spray-painted all the parts before attaching the electrical components.

//05 final assembly

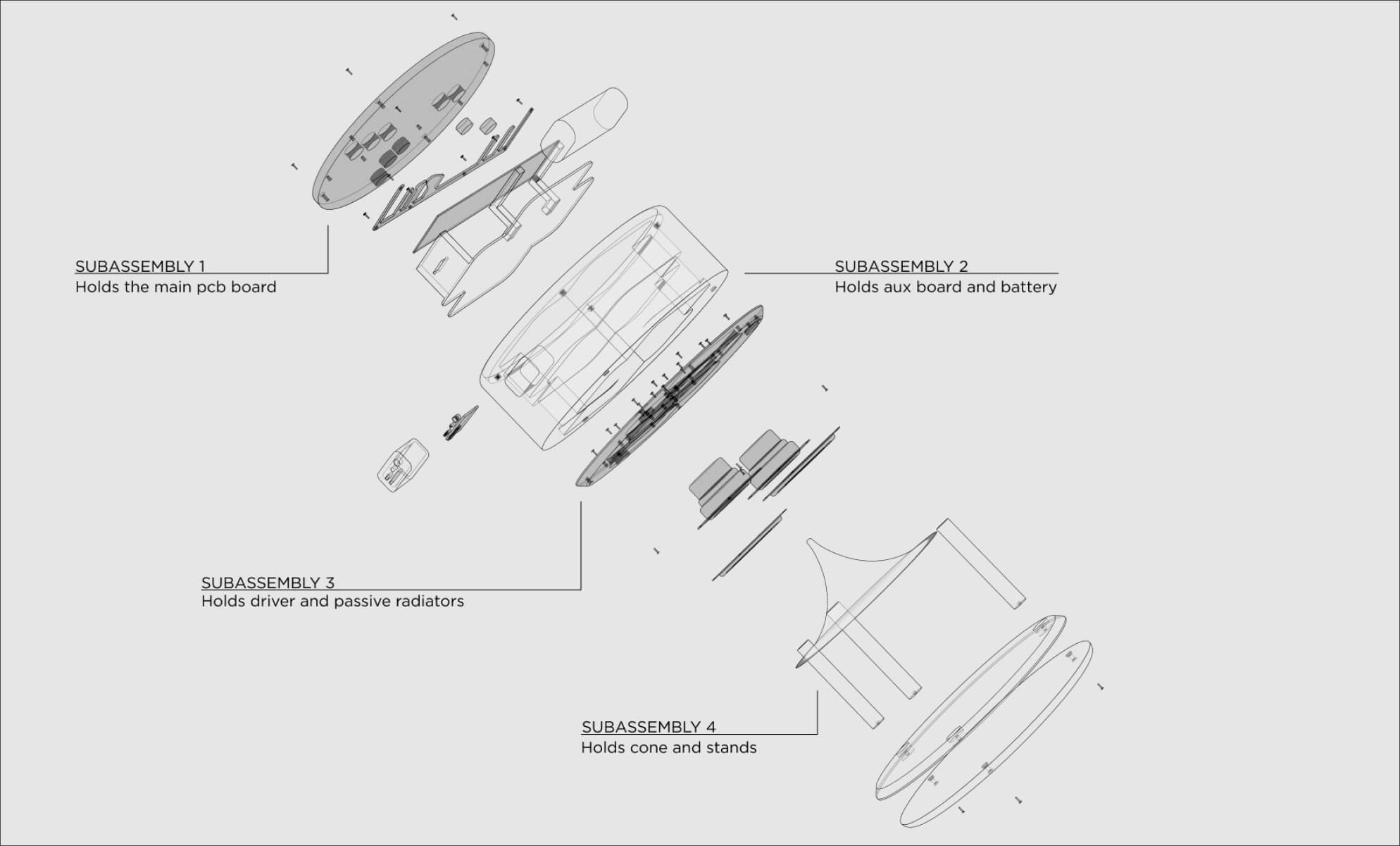

i assembled the painted parts into the 4 subassemblies before finally screwing everything together.